When it comes to modern performance vehicles, transmission technology is a critical factor in optimizing power delivery, fuel efficiency, and driving dynamics. Two notable systems that play an important role in this aspect are the Dual-Clutch Transmission (DCT) and the Multi-Plate Clutch system. Though they might seem related at first glance, they serve different purposes and function in distinct ways. Here's a detailed comparison to understand their differences and advantages.

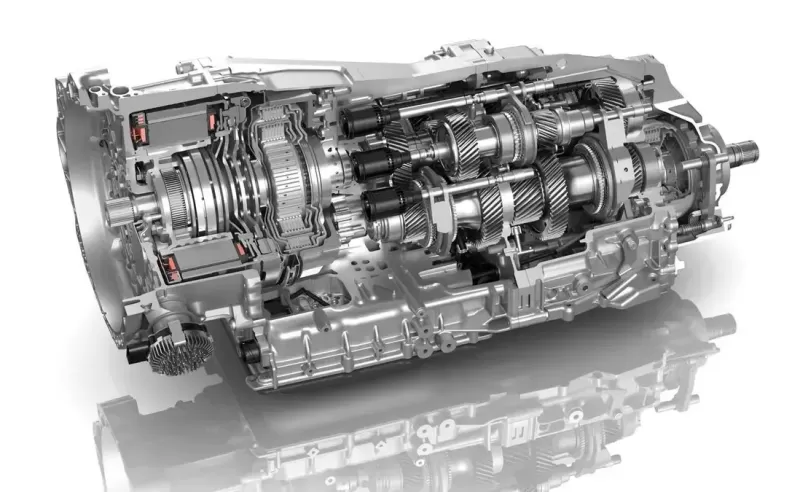

The Dual-Clutch Transmission (DCT) is a type of automated manual transmission (AMT) that uses two separate clutches for odd and even gear sets. It combines elements of both manual and automatic transmissions to deliver rapid gear shifts without the need for a torque converter, offering faster and more efficient power transfer.

How It Works

Two Clutches: The DCT uses two clutches, one for odd gears (1, 3, 5, etc.) and the other for even gears (2, 4, 6, etc.). These clutches are electronically controlled, and the next gear is pre-selected by the second clutch while the first one disengages.

Seamless Shifting: When you accelerate, the system shifts between the odd and even gears by switching from one clutch to the other, ensuring minimal power loss and nearly seamless transitions.

Automation: Unlike traditional manuals, the DCT is fully automatic, though some systems allow for manual override through paddle shifters or gear levers.

Advantages

Fast Shifts: One of the major advantages of a DCT is the lightning-fast gear shifts, usually faster than a human can achieve with a manual transmission.

Fuel Efficiency: With fewer power losses during gear changes, DCTs are more fuel-efficient than traditional automatic transmissions.

Performance-Oriented: DCTs are preferred in performance cars because they allow for rapid gear changes that aid acceleration and enhance the overall driving experience.

Smooth Operation: The pre-selection of gears ensures minimal interruption in torque delivery, resulting in a smoother drive.

Disadvantages

Complexity: The DCT system is more mechanically and electronically complex, which can result in higher maintenance costs.

Weight: DCT units tend to be heavier than traditional manual or automatic transmissions, which can slightly affect the vehicle’s weight-to-power ratio.

Low-Speed Behavior: In some systems, DCTs can feel jerky at lower speeds, particularly during parking or stop-start traffic, although modern versions have improved significantly.

A multi-plate clutch is a type of clutch that uses multiple friction plates to engage and disengage the transmission from the engine. This system is primarily used in high-performance applications, including motorcycles, racing cars, and high-performance road cars. The multi-plate clutch is designed to handle higher torque loads and provide a better grip compared to a single-plate clutch.

How It Works

Multiple Plates: Instead of just one friction plate, the multi-plate clutch uses several friction plates stacked together. This increases the surface area available for friction, allowing for higher torque capacity and better power delivery.

Compact Design: The multi-plate setup allows for a smaller clutch diameter, making it ideal for applications where space is limited, such as in motorcycles or high-performance vehicles.

Manual or Automatic Operation: Multi-plate clutches can be used in both manual and automatic systems, depending on the application.

Advantages

Higher Torque Handling: The additional friction surfaces allow multi-plate clutches to handle significantly more torque than single-plate designs, making them ideal for high-performance and racing applications.

Compact Size: The compact nature of a multi-plate clutch allows it to fit into smaller spaces, which is crucial for motorcycles and some compact high-performance cars.

Durability: Multi-plate clutches are often more durable in high-stress environments, as they can distribute heat and wear more evenly across the plates.

Disadvantages

Cost: Multi-plate clutches tend to be more expensive to manufacture and replace due to the complexity and number of components involved.

Maintenance: Given their performance focus, multi-plate clutches may require more frequent maintenance, especially in high-torque applications where wear is accelerated.

Heavier Pedal Feel: In manual systems, the use of a multi-plate clutch can result in a stiffer or heavier pedal feel, which may not be ideal for everyday driving.

The Dual-Clutch Transmission and Multi-Plate Clutch systems cater to different segments of the automotive world. DCT is preferred for high-performance road cars where quick, smooth shifts and fuel efficiency are critical, while the Multi-Plate Clutch is more suited for high-torque, high-performance applications like racing, motorcycles, or supercars where torque handling and compactness are essential.

In choosing between these two systems, it often comes down to the intended use of the vehicle. If you’re looking for a balance of comfort, speed, and daily drivability, a DCT is the way to go. If you need a system that can withstand extreme performance and heavy torque loads, particularly in racing or specialized vehicles, the Multi-Plate Clutch is likely the better choice.

Wael is an automotive content writer specializes in creating written content for Motor 283. Producing a wide range of content, including blog posts, articles, product descriptions, reviews, and technical guides related to cars, trucks, motorcycles, and other vehicles, with an unprecedented passion for cars, and motorcycles.