In the realm of automotive engineering, the rotary engine stands out as an innovative and unique powertrain design. Developed by German engineer Felix Wankel in the 1950s, the rotary engine provides an alternative to the conventional piston-driven combustion engine. With its compact size, high power-to-weight ratio, and smooth operation, the rotary engine has captivated the imagination of enthusiasts and engineers alike. In this article, we will explore the inner workings of the rotary engine and shed light on its operational principles.

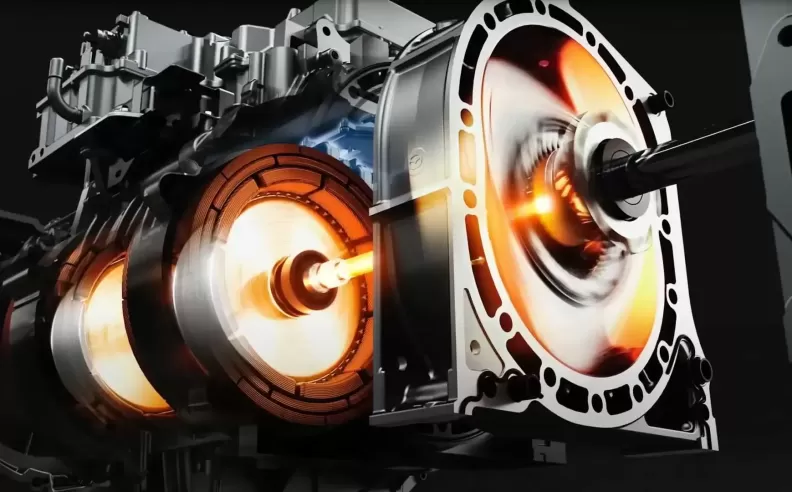

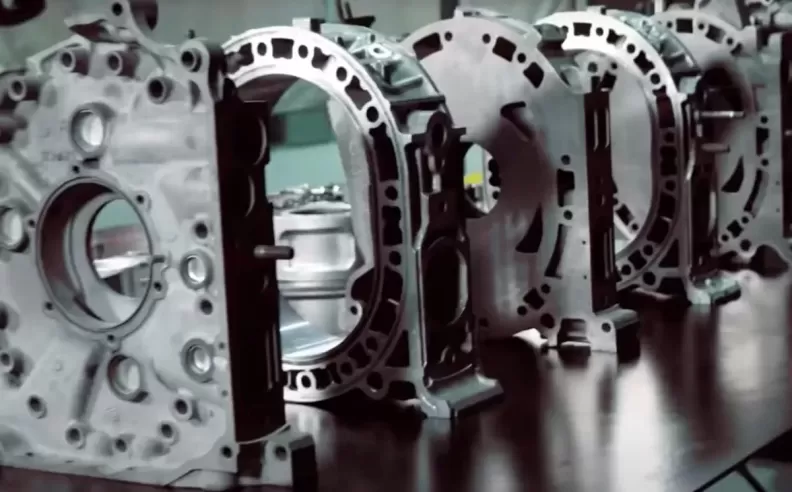

At the heart of the rotary engine lies a triangular rotor, often referred to as the "Wankel rotor," which rotates within an epitrochoidal (oval-shaped) housing. This simple yet ingenious design eliminates the need for reciprocating pistons, connecting rods, and valves found in traditional internal combustion engines. Instead, the rotary engine achieves the four-stroke cycle—intake, compression, combustion, and exhaust—within a single revolution of the rotor.

Intake: As the rotor turns, one face of the triangular rotor—the "trochoid chamber"—creates a variable-volume chamber between the rotor and the housing. As the chamber expands, it draws in a mixture of air and fuel through the intake port.

Compression: As the rotor continues to rotate, the chamber reduces in volume, compressing the air-fuel mixture. The compression ratio is defined by the shape of the housing, rotor, and apex seals that prevent leakage.

Combustion: When the compressed mixture reaches the spark plug, it ignites, propelling the rotor forward. The resulting expansion forces the rotor to continue rotating, converting the chemical energy of the fuel into mechanical energy.

Exhaust: As the rotor completes one revolution, the exhaust port aligns with the trochoid chamber, allowing the combustion gases to exit the engine. The spent gases are efficiently expelled due to the rotor's motion and the shape of the housing.

High Power Density: The compact size of the rotary engine allows for a high power-to-weight ratio, making it suitable for lightweight sports cars and aircraft. It produces a smooth and linear power delivery, offering a unique driving experience.

Reduced Vibration: Compared to piston engines, rotary engines exhibit less vibration since they have fewer reciprocating parts. This characteristic contributes to improved engine longevity and reduced wear and tear.

Simplified Design: With fewer components and moving parts, the rotary engine has a simpler design, making it easier to manufacture and maintain.

Fuel Efficiency: Rotary engines traditionally face challenges in achieving high fuel efficiency, primarily due to the design's inherent characteristics. The combustion chamber shape and relatively large surface area can lead to increased heat loss and incomplete combustion, affecting overall efficiency.

Oil Consumption: Rotary engines require oil for lubrication, and due to their unique design, a small amount of oil enters the combustion chamber during operation. This consumption necessitates regular monitoring and refilling of oil levels.

Emissions and Environmental Concerns: Historically, rotary engines have struggled to meet stringent emissions standards due to combustion inefficiencies. As environmental regulations become stricter, addressing emissions and fuel efficiency concerns becomes crucial for the future of rotary engines.

Wael is an automotive content writer specializes in creating written content for Motor 283. Producing a wide range of content, including blog posts, articles, product descriptions, reviews, and technical guides related to cars, trucks, motorcycles, and other vehicles, with an unprecedented passion for cars, and motorcycles.