In the world of automotive engineering, the suspension system holds a critical role, ensuring a smooth and controlled ride for both drivers and passengers. This intricate mechanism acts as a mediator between the car and the road, mitigating the impact of uneven surfaces, bumps, and potholes. Car suspension is not just about comfort but also plays a crucial role in maintaining vehicle stability, safety, and handling. In this article, we delve into the fascinating world of car suspension, exploring its different types, components, and the science behind this essential automotive system.

The primary purpose of a car's suspension system is to maintain optimal tire contact with the road surface, ensuring maximum traction, stability, and control. A well-designed suspension system achieves this by absorbing and dissipating the energy generated when a vehicle encounters imperfections in the road. By doing so, it prevents excessive body movement, vibrations, and bouncing that could otherwise lead to an uncomfortable and unsafe ride.

There are several types of suspension systems commonly used in automobiles, each offering different advantages based on the vehicle's intended use and design philosophy. Some of the most common suspension types include:

Independent Suspension: This type allows each wheel to move independently of the others, resulting in better ride quality and handling. There are various subtypes of independent suspension, such as double wishbone, multi-link, and MacPherson strut.

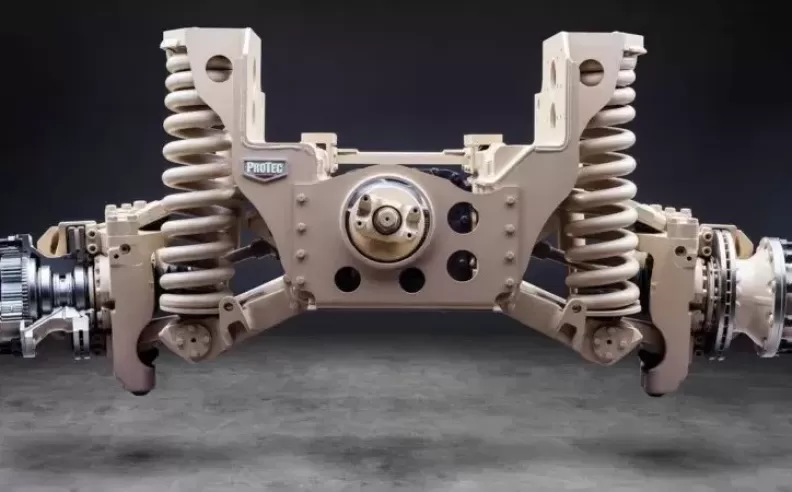

Solid Axle Suspension: Solid axle suspensions connect the wheels on each side of the vehicle, making them move together. This type is often found in trucks and off-road vehicles for their robustness and simplicity.

Air Suspension: Utilizing air-filled rubber bags or bellows, air suspension systems offer adjustable ride height, providing a more luxurious ride and the ability to adjust for various driving conditions.

Active Suspension: An advanced suspension system that uses electronic sensors and actuators to adapt the suspension's characteristics in real-time, improving comfort and handling simultaneously.

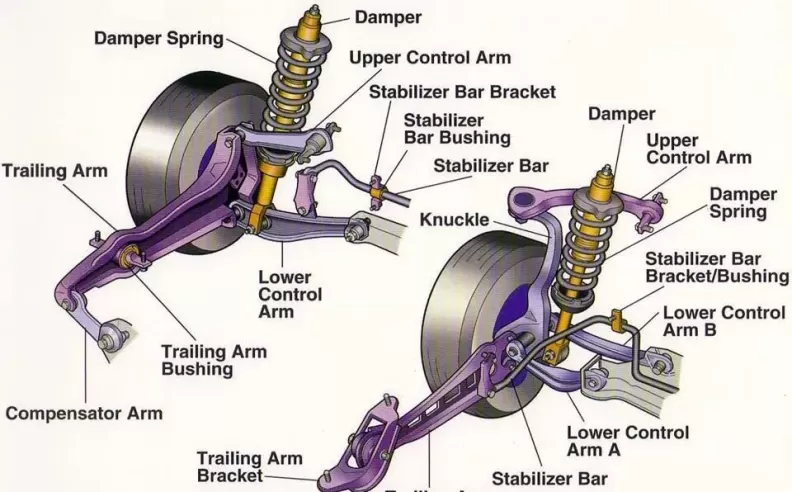

A typical car suspension system comprises various components, each contributing to its overall function. These include:

Springs: The springs are responsible for supporting the vehicle's weight and absorbing shocks from the road. Common types of springs include coil springs, leaf springs, and air springs.

Shock Absorbers (Dampers): Shock absorbers, or dampers, work in conjunction with springs to control the motion of the suspension. They dampen the oscillations caused by the springs' compression and rebound, helping maintain tire contact with the road.

Struts: A strut is a structural component that combines a shock absorber and a spring into a single unit. It is often used in MacPherson strut-type independent suspension systems.

Control Arms: Control arms connect the suspension components to the vehicle's chassis, allowing movement while maintaining stability and control.

Sway Bars (Stabilizer Bars): Sway bars reduce body roll during cornering by connecting the left and right sides of the suspension. This enhances stability and handling.

Designing an efficient suspension system is a delicate balancing act between various factors, including ride comfort, handling, durability, and cost. Engineers must consider factors like vehicle weight distribution, center of gravity, tire characteristics, and the intended purpose of the vehicle. Computer-aided design and simulation tools play a vital role in fine-tuning suspension systems, allowing engineers to optimize their performance and safety.

Wael is an automotive content writer specializes in creating written content for Motor 283. Producing a wide range of content, including blog posts, articles, product descriptions, reviews, and technical guides related to cars, trucks, motorcycles, and other vehicles, with an unprecedented passion for cars, and motorcycles.