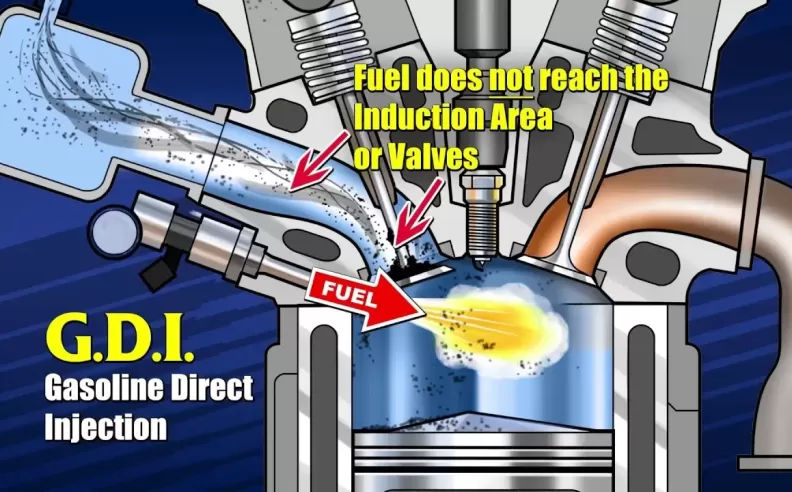

As the automotive industry continues to evolve at a rapid pace, manufacturers constantly push the boundaries of technology to enhance performance, efficiency, and sustainability. One of the most significant advancements in internal combustion engines is Gasoline Direct Injection (GDI). This fuel injection technology revolutionized engine efficiency by delivering fuel directly into the combustion chamber. But how does it work, and why has it become the standard in modern vehicles?

In the early days of internal combustion engines, carburetors were the primary method for mixing air and fuel before combustion. These systems, though effective at the time, were not efficient, often leading to fuel waste and increased emissions. As automotive engineering advanced, manufacturers introduced electronic fuel injection (EFI) systems, which used fuel injectors to spray gasoline into the engine’s intake manifold.

However, to maximize power while improving fuel economy, direct fuel injection (GDI) technology emerged. Unlike traditional systems, which mix fuel and air before entering the cylinder, GDI injects fuel directly into the combustion chamber, ensuring a more precise and efficient burn.

The first significant application of direct fuel injection appeared in Mercedes-Benz aircraft engines, followed by the legendary Mercedes 300 SL, a race car that benefited from this cutting-edge system. Later, Mitsubishi played a key role in bringing GDI technology to mainstream production vehicles, setting a new benchmark for efficiency and performance.

At the core of GDI technology are two essential components: the fuel pump and high-pressure injectors. Unlike conventional fuel injection systems, which operate at relatively low pressure, GDI engines use two fuel pumps:

The low-pressure pump delivers fuel from the tank at around 2-3 bar.

The high-pressure pump increases this pressure to 200 bar or more before sending it directly into the combustion chamber.

Once the fuel reaches the cylinder, precision-engineered injectors spray it as a fine mist, allowing for an optimal fuel-air mixture. The result? More power, improved fuel efficiency, and reduced emissions.

Modern engines often combine both GDI and EFI systems, particularly in high-performance V6 and V8 engines. These engines feature dual injection systems, with multiple fuel injectors per cylinder.

Gasoline Direct Injection has reshaped the way modern engines perform, offering an ideal balance between power, fuel economy, and reduced emissions. As car manufacturers continue refining this technology, GDI remains a crucial innovation in the quest for cleaner and more efficient internal combustion engines.

Started my career in Automotive Journalism in 2015. Even though I'm a pharmacist, hanging around cars all the time has created a passion for the automotive industry since day 1.